ISO 9001:2015 Certified Excellence

Commitment to zero-defect manufacturing through rigorous quality control at every stage of production.

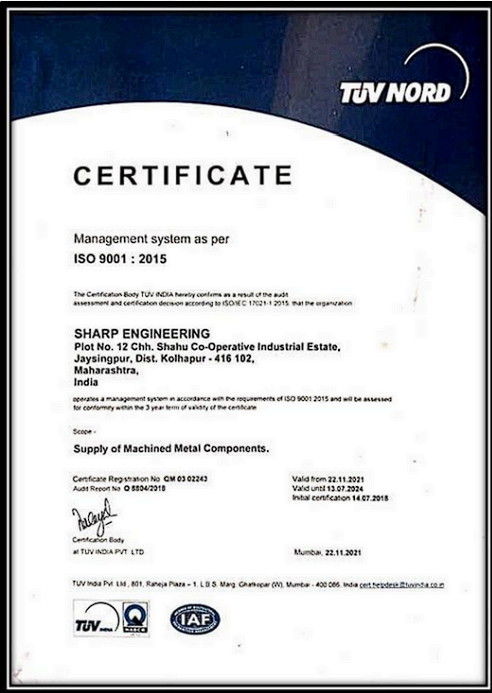

ISO 9001:2015 Certified

Sharp Engineering is proud to be ISO 9001:2015 certified, demonstrating our commitment to maintaining international quality management standards. This certification validates our systematic approach to quality control and continuous improvement.

Our quality management system ensures that every component we manufacture meets or exceeds customer specifications and industry benchmarks.

Quality Policy

At Sharp Engineering, quality is not just a goal but a fundamental principle that guides every aspect of our operations. We are committed to delivering precision-machined components that consistently meet and exceed customer expectations.

Our ISO 9001:2015 certification reflects our dedication to maintaining the highest standards of quality management, continuous improvement, and customer satisfaction.

Quality Assurance

Rigorous inspection at every production stage

Continuous Improvement

Ongoing process optimization and enhancement

Industry Benchmarks

Meeting and exceeding industry standards

Advanced Inspection Equipment

Our quality assurance laboratory is equipped with state-of-the-art digital measuring instruments to ensure precision and accuracy in every component we manufacture.

Digital Height Gauge

✓Digital Micrometer

✓Digital Vernier Caliper

✓Granite Surface Plate

✓Quality Control Process

Every component undergoes rigorous inspection at multiple stages to ensure zero-defect manufacturing.

Material Inspection

Verification of raw material specifications and quality before production begins.

In-Process Check

Continuous monitoring during machining operations to maintain tight tolerances.

Final Inspection

Comprehensive testing of finished components against specifications.

Documentation

Complete quality records and traceability for every batch produced.

Quality Commitments

Zero Defect Goal

We strive for zero-defect manufacturing through comprehensive quality control measures, skilled workforce, and continuous process improvement initiatives.

100% Inspection

Every component undergoes thorough inspection using advanced measuring instruments to ensure compliance with specifications and quality standards.

Continuous Improvement

Regular review of processes, adoption of best practices, and investment in technology to enhance quality and operational efficiency.

Customer Satisfaction

Committed to exceeding customer expectations through quality products, timely delivery, and responsive service at every touchpoint.

Certified Quality Management System

Our ISO 9001:2015 certification demonstrates our commitment to maintaining international quality management standards and delivering consistent, high-quality products to our customers.

Experience Our Quality Commitment

Partner with Sharp Engineering for ISO-certified precision components.